In the SphereWMS system, picked material may be required to go through a quality assurance step that is called "Pick Validation" before a shipment's post is permitted. Pick Validation is done to confirm that the physical shipment matches the shipment according to the system.

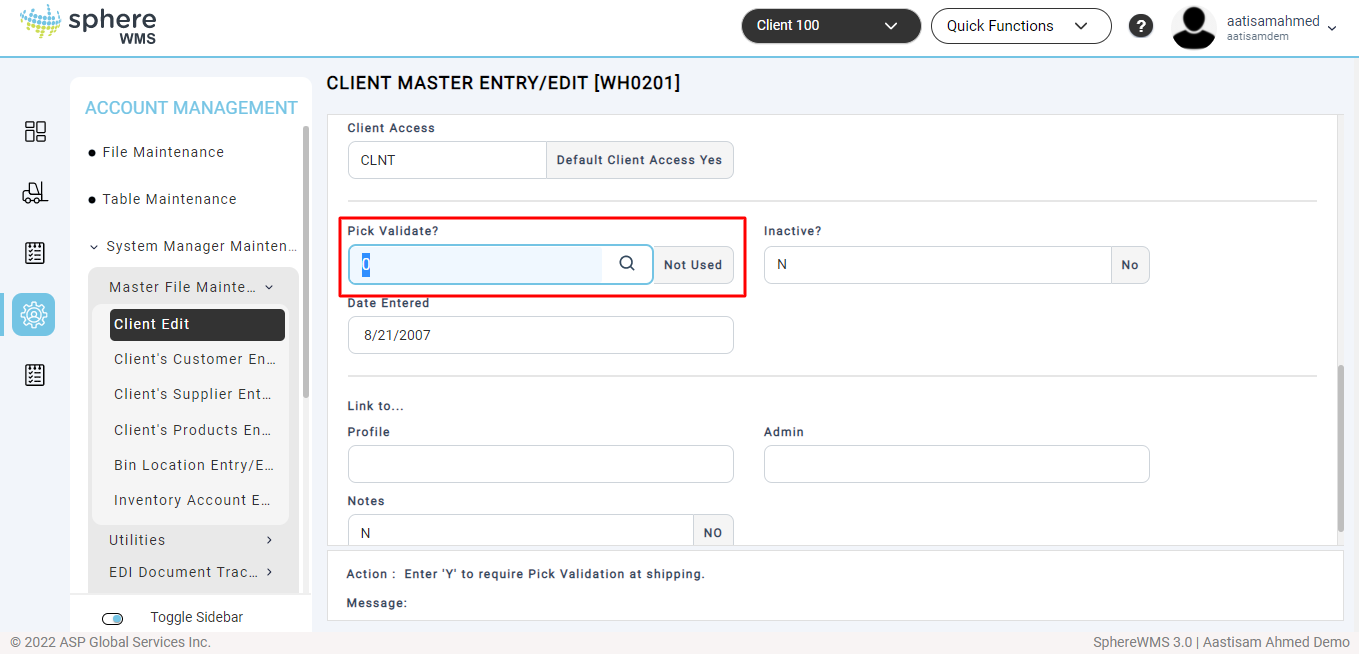

Whether Pick Validation is a requirement is determined by a setting in the Client Master.

If the "Pick Validate?" option in the Client Master is set to a "Y", all shipments must go through Pick Validation before the post is allowed.

Pick Validation is done after Order Allocation is completed. Pick Validation applies to orders allocated by using "Auto-Allocation" and "Alloc by Order#" only (i.e. systemic allocation). Manually allocated material is not required to go through the Pick Validation step.

To conduct Pick Validation, access the Order/Shipment Processing Menu and select "Pick Validation".

The user inputs or scans the Order Number, followed by the "Scan Line". The Line ID is in the format "xxxxxxYYY" where "xxxxxx" is the Order Number and "YYY" is the line number.

The Order Print has the Line ID in a barcode format for scanning purposes.

After entering the Line ID, the system prompts the user to enter or scan the line item's Product Code. If the entered Product Code does not match the line item, an error message displays.

If the correct Product Code is entered, the system then prompts the user for inventory information (such as Serial# and/or Lot# and Bin Location) based on the order line's product attributes.

Product Attributes

Based on the line's Product Master File settings, the Pick Validation process prompts for any required information. As a result of products having different attributes, the screen changes based on the Product Code being validated. See Products for more information on product master inventory attributes.

After all of the required Pick Validation information is entered, the system prompts the user to confirm the Quantity. The system then checks for matching the allocated inventory to ensure the physical material matches the system's information. If there is a mismatch, an error message displays.

If the allocated inventory is found and the pick is validated, the "Qty/Acc" is incremented accordingly. If the total Quantity Accumulated is then equal to the Quantity Allocated, the system will alert the user that the line item has been fully validated.

Repeat for each line on the order.

Exiting Pick Validation

To exit a Pick Validation screen, press ESC to move up one field at a time. Pressing ESC at the first question exits the screen and returns the user to the menu.

View Pick Validation Progress

Any time after the user has entered the Order# in the Pick Validation screen, the F5 Function Key may be selected to print a Pick Validation Progress Report. Once all allocated material is validated, the shipment may be posted.

Any time after the user has entered the Order# and the Scan Line, the F4 Function Key may be selected to display Pick Validation Progress Inquiry.

Press ESC to exit the F4 Function Key Inquiry and return to the Pick Validation entry screen.